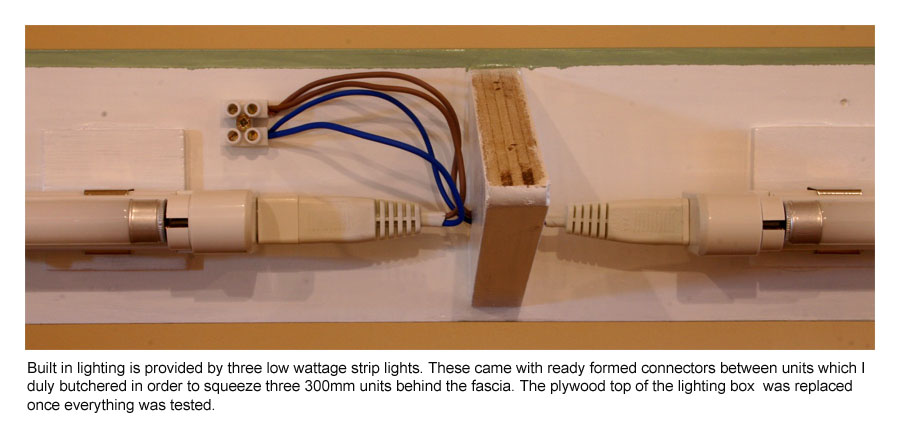

Lighting

Once the box had been painted/varnished to seal the surfaces, the built-in lighting was installed. This was mounted on the back of the front panel. A reflector was made out of 6mm ply and painted gloss white. This not only directs the light down onto the layout, it braces the top of the front panel and keeps the lighting out of the operators' eyes.

Trackwork

In order to reduce unwanted noise, I opted to use 10mm thick foam for the track bed. This came in the form of a carrymat from the local outdoor shop. The track layout was printed out full size and used as a template to cut the foam which was then secured to the MDF base with strong double sided carpet tape.

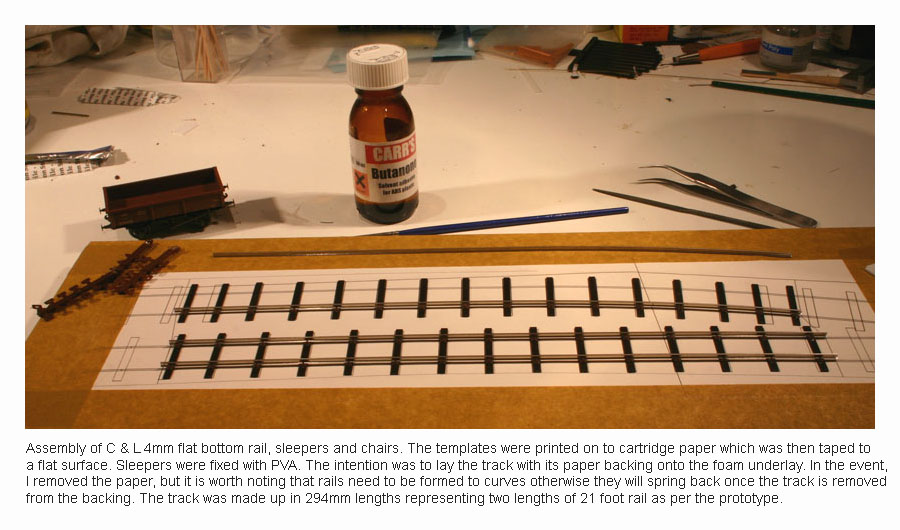

After much deliberation and checking of sizes and profiles, I decided to use C & L 4mm scale flat bottomed track, chairs and sleepers for the trackwork. I first built a short section to 16.5mm gauge and used this to experiment with different fillers and surfacing as the rails were all but buried on the prototype. I found that this gave rather too much 'sideplay' between wheels and track so decided to reduce it to 16mm on the layout. The Tallyllyn was officially built to 2'3" gauge, 15.75mm at 7mm/ft, but this was apparently subsequently widened to 2'4" to accommodate the 'long' wheelbase of the loco 'Talyllyn' on the tight curves, so I think 16mm is just fine.

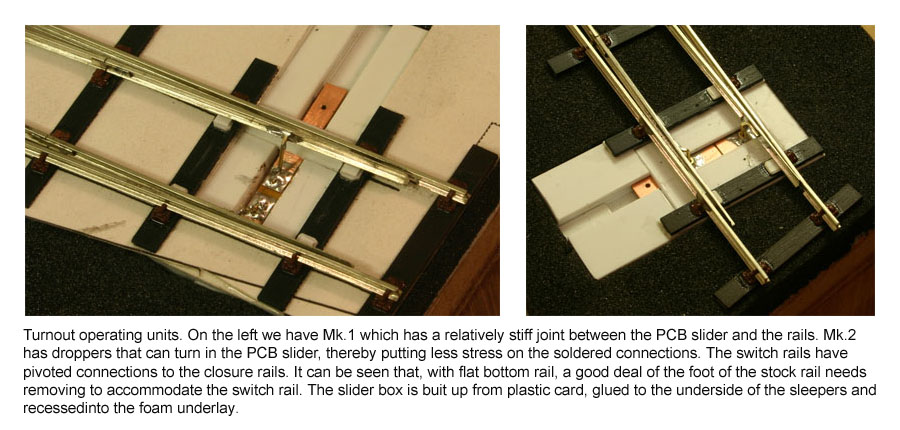

I printed off templates for the two turnouts and four sections of double track as I was only laying the track on the main board at this stage. The templates were then taped to a suitable offcut from some melamime faced shelving (I never throw anything away!). The plain sections of track were pretty straight forward once I had made myself a couple of simple track gauges from plastic card. The turnouts required a lot more work. The crossing vees were filed up in the vice using the template as a guide. If I had more to make I would probably make up a jig to speed up the process. They were then soldered up using high melt solder. As the sleepers will be hidden, I was able to solder a strip of pcb under the vee that would also take the ends of the wing rails and provide the switched electrical connection. The rest of the turnout was then assembled working out from the crossing vee. A lot of filing is required on both the switch rails and stock rails, largely due to the width of the foot of the flat bottomed rail. It is very important to get a snug fit between the rails to prevent derailment due to stock trying to follow both routes through the turnoput at the same time! On the prototype, the heels of the switch rails are held in purpose built chairs. I didn't fancy trying to make scale replicas so opted to fabricate a hinged joint between the switch rails and closure rails. Imagine a pair of fishplates soldered to the switch rail only but with a pinned joint to the closure rail. Tissue paper inserted between the rail and the plates will prevent them becoming accidentally soldered together and can be removed later with a pair of tweezers. I made up some slide chairs from plastic card.

The turnout units are illustrated above and are fairly self explanatory. Basically a box was made up which enables the PCB slider to move freely backwards and forwards while preventing any vertical movement. This ensures that the ends of the switch rails can be kept at the correct height. Remember to leave gaps under the slider for the protruding ends of the connections to the rails and the operating wire. Solder the connection to one switch rail, place a spacer between that and the stock rail to set the correct flangeway, clip the other switch rail to its stock rail and solder the second connection. If you have filed everything up correctly, each switch rail should fit snuggly against its neighbour while the flangeway on its opposite number is maintained.

Once all the track units had been assembled they were laid loose on the trackbed to make sure that everything lined up and the gaps between the ends of rails were consistent. False rail joints had been cut in the head of the rail with a mini cutting disk while still on the template. At this point, positions of electrical connections were determined and soft wire droppers soldered to the backs of the rails. These should be made reasonably long, they can always be trimmed later. Holes were bored through the track bed to match the positions of the droppers. The track was now laid, starting with the turnout at one end, bedding each sleeper with a generous helping of PVA. Once happy with the positioning, the track was weighted and left while the glue set. This procedure continued across the layout, finishing with the second turnout. I had left the stock rails on this overlong to take up any minor discrepancy in the setting out but in fact they were spot on and the extra length had to be removed later.

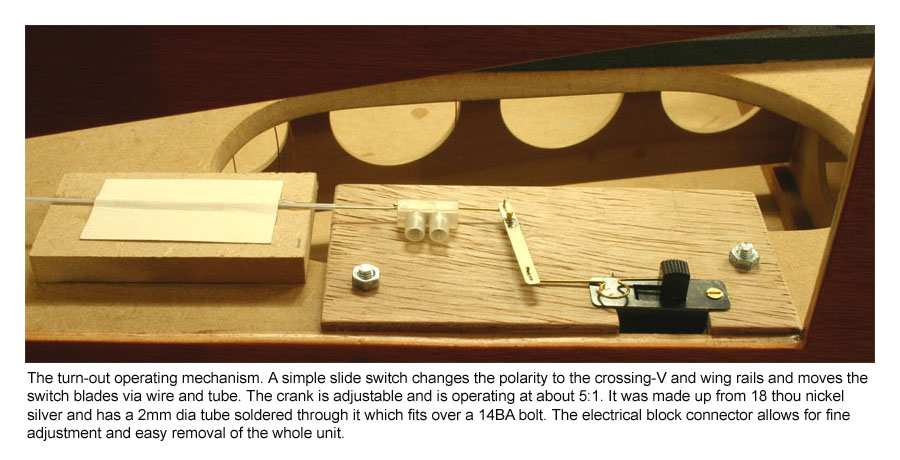

With such a basic layout, wiring is very simple, especially with DCC. One positive and one negative cable were run under the baseboard with screwed block connectors at each end and at intermediate points to pick up the droppers. This was a new departure for me as I have previously soldered all the joints under the baseboard. Connections were also made from the main cable runs to the turnout slide switches and back to the crossing vee/wing rails.

The above photo clearly illustrates the method of operating the turnouts. These switches are accessible through openings in the back of the layout and will be concealed by the scenery.