Chassis (contd.)

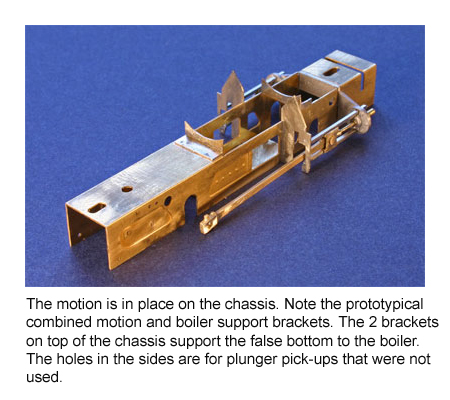

The last component of the motion assembly was the support bracket. The one supplied with the kit bore no resemblance to the real thing. On the prototype the boiler acts as part of the frame and the motion bracket is extended to act as an intermediate support. I decided to do the same on the model. This necessitated cutting slots in the white metal with a piercing saw. The joint in the footplate at this point is detailed in the casting, unfortunately the location isn't correct. I opted to stick with the location although this meant that the support came too far back on the boiler which could cause problems in the future.

The rear of the cylinders comes as a single casting. I drilled out the centres and inserted short lengths of brass tube to represent the gland and give a more positive location for the piston rods.The final fabrication was the slide bars. These were made from the 1mm x 1mm nickel silver bar supplied with the kit once it had been straightened. The outer ends were filed and carefully bent to as near to the correct profile as possible as on the prototype they are bolted to the face of the motion bracket, not let into it as per the kit design.

The motion could now be assembled. The motion brackets were soldered in place centrally between the cut outs in the side frames. The cylinder casting was fitted into the chassis and temporarily held in place with blue tack and the slide bars threaded into the slots provided. A top slide bar was then soldered to the motion bracket, a cross head assembly was slid between the slide bars and the bottom one was clamped in place against the motion bracket. Once I was happy that the slide bars were parallel and the cross head was moving freely, the bottom slide bar was soldered to the motion bracket. This was then repeated on the other side. Finally, the other ends of the slide bars were secured to the cylinders and the cylinder assembly glued in place, checking that everything was square and that both cross heads still moved freely.

Brackets were now made up to support the false bottom to the boiler and soldered in position. The false bottom itself was laminated from four layers of 10 thou plastic card fixed to to 40 thou thick formers and base.

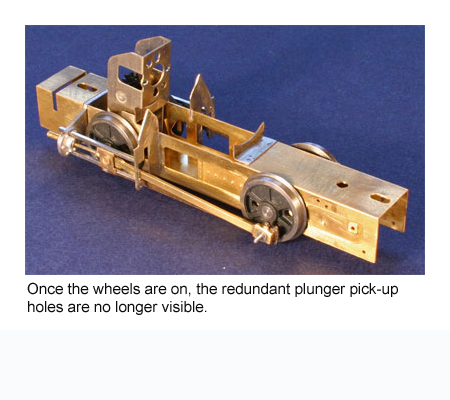

The wheel sets, gearbox and coupling rods were now dropped into place and the retaining plate fitted. The connecting rods were slid over the crank pins, the nuts fitted and the whole thing tested for free running. There was just a hint of binding on the right hand side which didappeared once the retaining plate was removed. A couple of strokes with the file cured the problem. There was rather too much slack on the rear crank pins so the bushes were gently filed until I was happy with the fit.

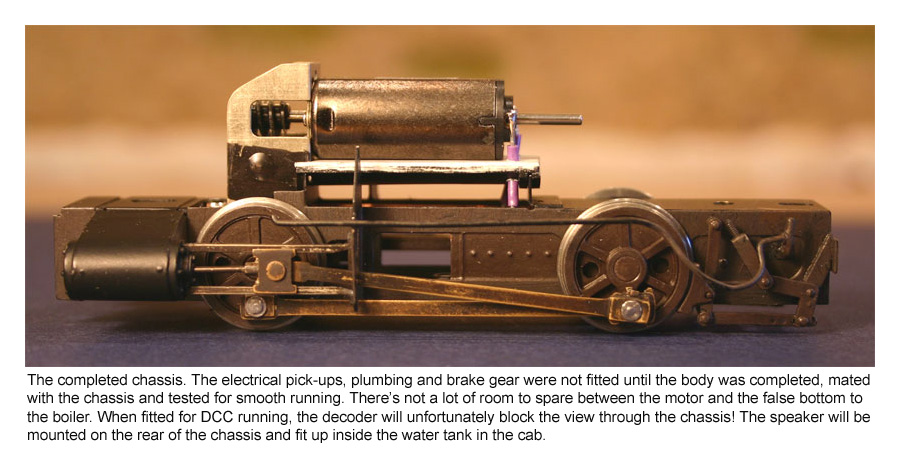

It was now time to bite the bullet and test the chassis under power which meant fixing the drive gear with loctite. After a suitable wait, the motor was fitted, the chassis placed on the rolling road, tempoary connections made to the motor and the power turned on. Thankfully everything still ran smoothly.

The rest of the white metal cylinder assembly was now glued in position. The inside of the cylinder covers needed an enormous amount of material removing to allow them to fit over the front and back castings.

At this point, I set the chassis aside and set to work on the body.